Explore the principles, applications, components, and future of High-performance Liquid Chromatography (HPLC), an essential tool in modern analytical science

What is High-performance Liquid Chromatography (HPLC)?

High-performance liquid chromatography, commonly abbreviated as HPLC, is an advanced form of liquid chromatography used for separating, identifying, and quantifying compounds in a mixture. It has become one of the most powerful analytical techniques in various industries, including pharmaceuticals, biotechnology, food safety, and environmental science.

At its core, HPLC operates based on the distribution of compounds between a mobile phase (liquid) and a stationary phase (solid material). A high-pressure pump pushes the mobile phase through a column filled with stationary phase material. When a sample mixture is injected, its components interact differently with the stationary phase, causing them to exit the column at different times — a process known as retention.

This technique is widely used for its:

- High sensitivity and resolution

- Reproducibility and reliability

- Capability to handle complex mixtures

Whether you’re testing drug purity in a pharmaceutical lab or analysing contaminants in a water sample, high-performance liquid chromatography provides accurate and timely results.

Why HPLC is Critical in Modern Science

In today’s world, data integrity, safety, and quality control are non-negotiable. HPLC meets these demands by offering:

- Accurate quantification

- Detection of trace-level impurities

- Versatile applications across liquid-soluble compounds

The pharmaceutical industry, in particular, relies heavily on high-performance liquid chromatography for drug development, validation, and regulatory submissions.

History and Evolution of High-performance Liquid Chromatography

Understanding the origins of high-performance liquid chromatography offers perspective on how far modern analytical chemistry has progressed.

Early Chromatography: The Foundation:

The roots of chromatography trace back to the early 1900s when Russian botanist Mikhail Tswett used a rudimentary column packed with calcium carbonate to separate plant pigments. The term “chromatography,” derived from the Greek for “colour writing,” was born.

Initially, liquid chromatography techniques were:

- Slow and imprecise

- Operated under gravity (no pressure)

Suitable for simple mixtures only

Emergence of HPLC in the 1960s–70s:

The 1960s brought advancements in technology, particularly in pumps and detectors. Scientists began to apply high pressure to force the liquid mobile phase through more tightly packed columns, leading to higher resolution and faster analysis — the core idea behind HPLC.

By the 1970s, high-performance liquid chromatography became a recognised analytical method. Key developments included:

- Binary pumps and gradient elution systems

- Improved column materials (e.g., C18 silica)

- UV detectors and later, photodiode array detectors

From HPLC to UHPLC:

The 2000s saw the advent of Ultra-High Performance Liquid Chromatography (UHPLC), which uses even smaller particle sizes (<2 μm) and operates at pressures up to 15,000 psi. This allows for:

- Faster run times

- Sharper peak resolution

- Lower solvent consumption

Despite these advancements, the core principles of high-performance liquid chromatography remain consistent with Tswett’s original concept of separation based on molecular interactions.

How Does High-performance Liquid Chromatography Work?

Understanding the working principle of high-performance liquid chromatography is key to appreciating its analytical power. HPLC separates compounds based on their differing interactions with two phases — a mobile phase (liquid) and a stationary phase (solid particles inside a column).

Step-by-Step Overview of the HPLC Process:

1. Sample Injection:

A small volume of the liquid sample (typically 1–20 μL) is introduced into the flow of the mobile phase using an injector system.

2. Mobile Phase Flow:

The mobile phase — usually a mixture of solvents like water, methanol, or acetonitrile — is pumped under high pressure (up to 6,000 psi) through the column.

3. Separation in the Column:

The heart of the high-performance liquid chromatography system is the column, which contains tightly packed stationary phase particles (often silica-based). As the sample flows through:

- Components interact differently with the stationary phase.

- Some molecules travel faster due to weaker interactions, while others are retained longer.

4. Detection:

As the separated compounds exit the column at different times (retention times), they pass through a detector, typically a UV-Vis detector. The system records a chromatogram, displaying peaks that correspond to individual components.

5. Data Interpretation:

Each peak represents a compound, and its area or height is proportional to the concentration. This allows both qualitative and quantitative analysis.

Key Principle: Partitioning or Adsorption:

Depending on the type of HPLC, separation may be governed by:

- Partitioning (solubility between mobile and stationary phases)

- Adsorption (surface interaction with stationary particles)

- Size exclusion

- Ion exchange

The versatility of high-performance liquid chromatography lies in its ability to separate a wide range of compounds — from small organic molecules to large biomolecules — with remarkable accuracy.

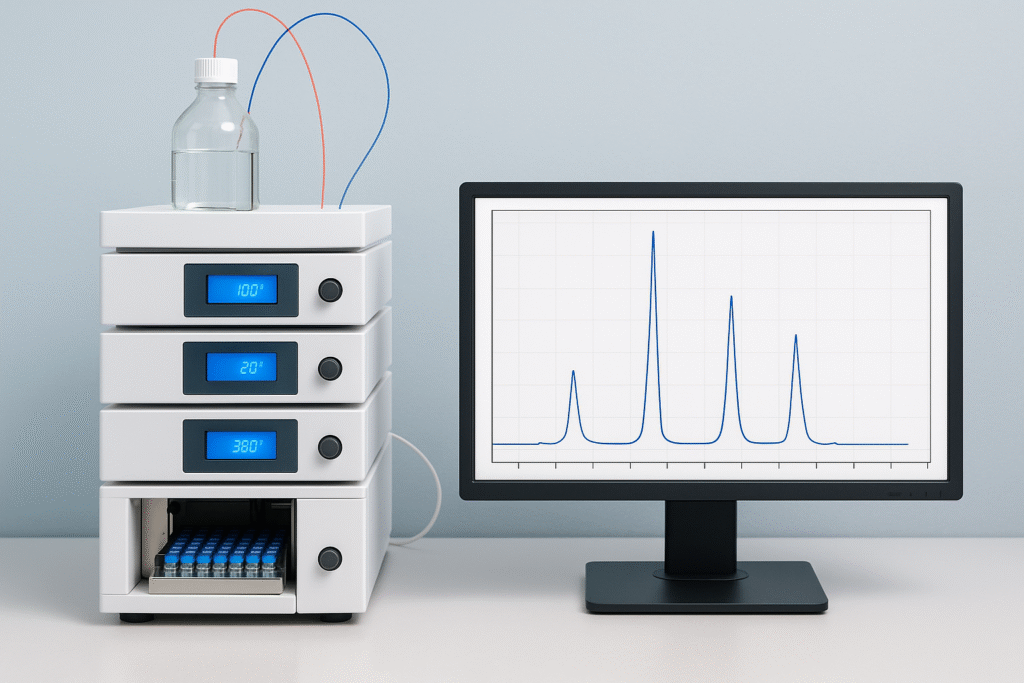

Components of an HPLC System

To grasp how HPLC achieves such high precision, it’s essential to understand its core components. Every high-performance liquid chromatography system comprises several integrated modules, each performing a critical role.

1. Solvent Reservoirs:

These containers hold the mobile phase solvents. Depending on the method, single or mixed solvents may be used. Often, gradient elution is employed, where the ratio of solvents changes over time to improve separation.

2. Degasser:

Air bubbles in the mobile phase can interfere with detection and flow. A degasser removes dissolved gases through vacuum or membrane filtration before pumping.

3. Pump:

The pump delivers the mobile phase at a constant, high pressure, essential for driving it through the tightly packed column. Types include:

- Isocratic pumps (constant composition)

- Gradient pumps (changing solvent ratios over time)

4. Injector:

The injector introduces the sample into the mobile phase stream. In manual systems, this may be a loop injector; in automated systems, autosamplers ensure reproducibility.

5. Column:

The most critical part of the high-performance liquid chromatography system, the column is where the separation happens. It’s filled with stationary phase particles (typically C18 silica), which provide interaction sites for different analytes.

6. Detector:

The detector identifies and quantifies the analytes as they exit the column. Common detectors include:

- UV-Visible

- Photodiode Array (PDA)

- Fluorescence

- Refractive Index

- Mass Spectrometry (for LC-MS)

7. Data System (Chromatography Software):

Once the signal is received from the detector, chromatography software converts it into a chromatogram. It calculates:

- Retention time

- Peak area/height

- Concentration (based on calibration curves)

Each component is meticulously calibrated to ensure that high-performance liquid chromatography runs with exceptional precision and repeatability.

Types of High-performance Liquid Chromatography Techniques

One of the key strengths of high-performance liquid chromatography is its versatility. Depending on the nature of the analytes and the separation goals, several HPLC techniques are employed. Each offers unique advantages in terms of resolution, sensitivity, and suitability for different sample types.

1. Reverse Phase HPLC (RP-HPLC):

This is the most widely used form of high-performance liquid chromatography in pharmaceutical, environmental, and clinical labs.

- Stationary Phase: Non-polar (e.g., C18 or C8 silica)

- Mobile Phase: Polar solvents (e.g., water, methanol, acetonitrile)

- Mechanism: Hydrophobic interactions

- Use: Ideal for moderately polar to non-polar compounds

Why it’s popular: It offers high reproducibility, better peak symmetry, and compatibility with a wide range of detectors.

2. Normal Phase HPLC (NP-HPLC):

This is the original form of liquid chromatography but is less common today than reverse phase.

- Stationary Phase: Polar (e.g., unmodified silica)

- Mobile Phase: Non-polar solvents (e.g., hexane, chloroform)

- Mechanism: Adsorption based on polarity

- Use: Useful for separating isomers and polar compounds

3. Size Exclusion HPLC (SEC or GPC):

Also known as gel permeation chromatography (GPC), this technique separates molecules based on size.

- Stationary Phase: Porous gel particles

- Mechanism: Larger molecules elute first; smaller molecules enter pores and elute later

- Use: Analysis of polymers, proteins, and other macromolecules

4. Ion Exchange HPLC (IEX-HPLC):

This method separates ionic compounds based on charge interactions with the stationary phase.

- Stationary Phase: Charged resins (either cationic or anionic)

- Mechanism: Electrostatic attraction/repulsion

- Use: Separation of amino acids, proteins, and nucleotides

5. Affinity HPLC:

A highly selective method, affinity HPLC uses biological interactions for separation.

- Stationary Phase: Ligands that bind specifically to a target molecule

- Use: Purification of enzymes, antibodies, or receptor-ligand complexes

- Applications: Biopharmaceutical research and protein analysis

Each type of high-performance liquid chromatography has its own benefits depending on the sample matrix, target analytes, and regulatory requirements.

Applications of High-performance Liquid Chromatography

High-performance liquid chromatography is an indispensable analytical technique across multiple industries. Its ability to offer precise, reproducible, and high-resolution results makes it the method of choice for professionals working in quality control, research, safety testing, and clinical diagnostics.

1. Pharmaceutical Industry:

HPLC plays a central role in both drug development and post-market surveillance.

- Drug identification and assay

- Impurity profiling

- Stability testing

- Bioavailability studies

- Compliance with pharmacopeial standards (e.g., USP, BP)

Nearly every batch of a pharmaceutical product is analysed using high-performance liquid chromatography before release.

2. Food and Beverage Testing:

Food safety and authenticity are critical public health concerns. HPLC enables detection of:

- Pesticide residues

- Artificial sweeteners and preservatives

- Natural toxins (e.g., mycotoxins)

- Food additives and colourants

Sugar and vitamin content

3. Environmental Monitoring:

Environmental laboratories rely on high-performance liquid chromatography to monitor pollutants in air, water, and soil.

- Detection of herbicides and pesticides in water bodies

- Industrial effluent monitoring

- Analysis of polycyclic aromatic hydrocarbons (PAHs)

Groundwater and soil contamination analysis

4. Clinical and Biomedical Research:

HPLC is used to measure drug levels in blood, monitor disease biomarkers, and support diagnostics.

- Therapeutic drug monitoring (e.g., antiepileptics, immunosuppressants)

- Detection of hormones and neurotransmitters

- Protein and peptide mapping

- Metabolomics and lipidomics

5. Forensic Science:

In criminal investigations, high-performance liquid chromatography is used to identify substances such as:

- Illicit drugs

- Toxins and poisons

- Explosive residues

- Alcohol and related metabolites in biological fluids

In every industry, HPLC is valued for its precision, reproducibility, and adaptability — making it a cornerstone of modern analytical chemistry.

High-performance Liquid Chromatography in Quality Control (QC)

In the pharmaceutical industry, quality control (QC) ensures the safety, efficacy, and consistency of medicinal products. Among all analytical techniques, high-performance liquid chromatography stands out as the most trusted and widely used tool in QC laboratories.

Why HPLC is Essential in QC:

The primary goal of pharmaceutical QC is to confirm that a product complies with regulatory specifications at every stage — from raw material to finished dosage form. HPLC offers:

- High sensitivity and selectivity

- Rapid analysis time

- Quantitative accuracy

- Regulatory acceptance by FDA, EMA, MHRA, etc.

It is used in both small molecule and biological product testing.

Key QC Applications of HPLC:

1. Assay of Active Pharmaceutical Ingredients (APIs):

HPLC determines the exact amount of API present in a formulation, ensuring therapeutic consistency across all batches.

2. Impurity Profiling:

- Trace-level detection of impurities is critical to drug safety. HPLC can detect:

- Process-related impurities

- Degradation products

- Genotoxic impurities

3. Dissolution Testing:

Ensures that oral drugs release their active ingredient at the right rate and location in the body. HPLC analyses the dissolved sample over time.

4. Stability Studies:

Accelerated and long-term stability studies involve HPLC to detect degradation, ensuring shelf life accuracy.

5. Content Uniformity:

Ensures that each dosage unit (tablet, capsule, etc.) contains uniform drug content within acceptable limits.

Regulatory Compliance and Method Validation:

To ensure data reliability, HPLC methods used in QC must undergo method validation, adhering to ICH Q2(R1) guidelines. Parameters include:

- Specificity

- Linearity

- Accuracy

- Precision

- Detection and quantitation limits

- Robustness

High-performance liquid chromatography plays a non-negotiable role in maintaining regulatory compliance and consumer safety in the pharmaceutical world.

Advantages and Limitations of High-performance Liquid Chromatography

Like any analytical technique, high-performance liquid chromatography has its strengths and drawbacks. Understanding these helps in choosing the right method for a given application and managing laboratory expectations.

Advantages of HPLC:

1. High Sensitivity and Selectivity:

Capable of detecting compounds in parts-per-million (ppm) or parts-per-billion (ppb) levels, making it suitable for trace analysis.

2. Excellent Resolution:

HPLC can separate complex mixtures into individual components with minimal overlap, allowing accurate identification and quantification.

3. Versatility:

Applicable to a wide range of compounds — from small organics to proteins and nucleotides.

4.Speed and Efficiency:

With optimised methods, analysis time can be reduced to minutes while maintaining resolution.

5. Reproducibility:

When conditions are carefully controlled, HPLC offers excellent precision across multiple runs and analysts.

6. Regulatory Acceptance:

Recognised by global pharmacopeias and regulatory agencies, which simplifies compliance and audits.

Limitations of HPLC:

1. Cost:

Initial capital investment and ongoing maintenance of an HPLC system can be expensive, especially with advanced detectors like MS.

2. Solvent Consumption and Waste:

HPLC consumes significant volumes of solvents, which can be hazardous and costly to dispose of safely.

3. Method Development Time:

Developing a robust and validated HPLC method can take weeks, especially for complex formulations.

4. Sample Requirements:

HPLC generally requires the sample to be in liquid form and free of particulates, sometimes requiring extensive preparation.

5. Column Degradation:

Columns can degrade over time due to sample matrix or improper pH, requiring frequent replacement and optimisation.

Despite these limitations, the strengths of high-performance liquid chromatography make it indispensable in both routine analysis and advanced research.

Latest Trends in High-performance Liquid Chromatography

As science and technology evolve, so too does high-performance liquid chromatography. Recent innovations have improved speed, sensitivity, environmental impact, and automation, making HPLC more powerful and adaptable than ever.

Let’s explore the most significant trends transforming the future of HPLC.

1. Ultra-High Performance Liquid Chromatography (UHPLC):

UHPLC builds on traditional HPLC by using smaller particle sizes (<2 μm) and operating at much higher pressures (up to 15,000 psi). The benefits include:

- Faster separation times

- Sharper, better-resolved peaks

- Less solvent usage

Pharmaceutical companies now widely adopt UHPLC for faster throughput and regulatory compliance.

2. HPLC Coupled with Mass Spectrometry (HPLC-MS):

The integration of mass spectrometry (MS) with HPLC has become increasingly popular due to its unparalleled sensitivity and molecular identification power.

Applications include:

- Metabolomics and proteomics

- Drug development

- Biomarker discovery

- Environmental toxin monitoring

HPLC-MS is ideal for identifying unknown compounds, thanks to its ability to provide molecular weight and structural information.

3. Green Chromatography:

There is growing pressure to reduce the environmental impact of analytical labs. As such, “green chromatography” is gaining momentum.

- Reduction of toxic solvents

- Use of biodegradable mobile phases

- Miniaturised systems (micro-HPLC) to reduce waste

This eco-conscious approach aligns with green chemistry principles and regulatory push for sustainability.

4. Automated and Robotic HPLC Systems:

Automation helps eliminate human error and reduce turnaround time. Key innovations include:

- Autosamplers with cooling features

- Robotic vial handling

- Software that self-corrects pressure and flow inconsistencies

- Remote operation and cloud-based data logging

These advancements have made high-performance liquid chromatography more efficient, scalable, and user-friendly.

5. Real-Time Monitoring and PAT Integration:

The pharmaceutical industry is embracing Process Analytical Technology (PAT) — a regulatory initiative that integrates real-time monitoring into manufacturing.

HPLC systems are now being modified to:

- Provide in-process quality control

- Interface with other real-time analytics

- Enhance product lifecycle management

These modern trends reaffirm that HPLC continues to evolve as a cornerstone of precision analytics in a data-driven world.

Tips for Optimizing High-performance Liquid Chromatography Results

Even though high-performance liquid chromatography is known for its accuracy, achieving consistent and high-quality results depends on proper system handling and method development. Below are essential tips to help analysts optimise their HPLC runs.

1. Choose the Right Column:

- Match the column chemistry (e.g., C18, C8, phenyl) to the compound’s polarity and molecular weight.

- Use columns with narrow internal diameters for higher efficiency and lower solvent usage.

- Precondition new columns before use and store them properly when idle.

2. Optimize Mobile Phase Composition:

- Ensure compatibility with both analyte and detector.

- Adjust pH and buffer strength to improve peak shape.

- Filter and degas mobile phases to prevent pump cavitation or baseline noise.

- Use isocratic or gradient elution depending on sample complexity.

3. Maintain Flow Rate and Temperature:

- Maintain consistent flow rates (typically 0.5–1.5 mL/min) to ensure reproducible retention times.

- Some separations benefit from controlled column temperatures (e.g., 30–40°C) for better resolution.

4. Sample Preparation is Key:

- Filter all samples using 0.22–0.45 μm syringe filters to avoid clogging columns.

- Dilute or dissolve samples in the same solvent as the mobile phase for smoother integration.

- Use internal standards to monitor recovery and method consistency.

5. Regular Maintenance of HPLC System:

- Flush columns regularly with suitable solvents.

- Replace seals, filters, and tubing as needed.

- Validate system suitability before each batch with control standards.

- Calibrate detectors and autosamplers periodically.

By incorporating these strategies, laboratories can maximise the performance and lifespan of their high-performance liquid chromatography systems while ensuring reliable and repeatable results.

Frequently Asked Questions (FAQs) about High-performance Liquid Chromatography

Below are the most commonly asked questions regarding high-performance liquid chromatography, particularly in research, pharmaceutical, and quality control settings.

1. What is high-performance liquid chromatography used for?

HPLC is used to separate, identify, and quantify components in a mixture. Common applications include:

- Drug analysis in pharmaceuticals

- Impurity detection

- Food safety testing

- Environmental pollutant monitoring

Biomedical and forensic investigations

2. Is HPLC a qualitative or quantitative technique?

HPLC can be both:

- Qualitative, when used to identify the presence of specific compounds based on retention time and spectral data

- Quantitative, when used to measure the exact concentration of components using calibration curves and peak area

3. How is HPLC different from gas chromatography (GC)?

| Feature | HPLC | GC |

| Mobile Phase | Liquid | Gas |

| Sample Type | Thermally unstable or non-volatile | Volatile |

| Common Use | Pharmaceuticals, biomolecules | Solvents, alcohols, essential oils |

| Temperature | Ambient or controlled | High temperatures required |

HPLC is ideal for compounds that are not suitable for vapourisation.

4. What does a chromatogram show in HPLC?

A chromatogram is a graphical output from the detector that displays peaks representing individual components. Key details include:

- Retention time (identity)

- Peak area or height (concentration)

- Peak shape and symmetry (method performance)

5. What types of detectors are used in HPLC?

Some of the most widely used detectors include:

- UV-Vis detectors (standard)

- Photodiode Array (PDA) for spectral analysis

- Refractive Index (RI) for sugars and lipids

- Mass Spectrometry (MS) for molecular mass and structure

- Fluorescence detectors for high sensitivity in trace analysis

Each type serves different analytical needs based on sensitivity and compound characteristics.

see more articles

Curated List of Drug Approvals in 2024–2025: A New Era in Therapeutics

India’s Pharma Growth in 2025: A Global Healthcare Powerhouse